What are the legal requirements for BIPV?

Building-integrated photovoltaic (BIPV) modules/systems have to be compliant with both electro technical standards and existing building codes and practices, since they are both generators of electricity and part of the building envelope.

According to EN 50583, Parts 1 and 2, "Photovoltaics in buildings" [1], "Photovoltaic modules are considered to be building-integrated, if the photovoltaic modules form a construction product providing a function as defined in the European Construction Product Regulation CPR 305/2011 [2].”

Thus, the Building-integrated photovoltaic (BIPV) module is a prerequisite for the integrity of the building’s functionality. If the integrated photovoltaic module is dismounted (in the case of structurally bonded modules, dis-mounting includes the adjacent construction product), the photovoltaic module would have to be replaced by an appropriate construction product".

In conclusion, we can summarize that:

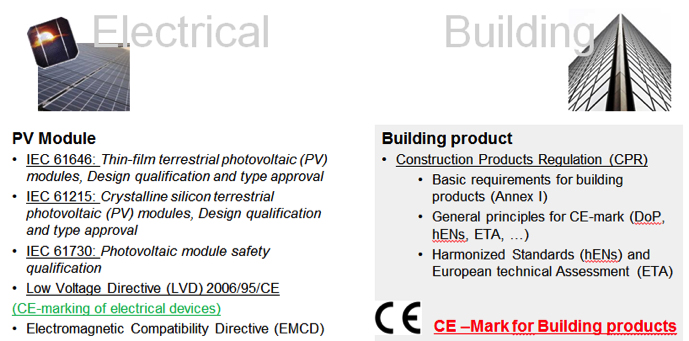

- BIPV elements, as part of the building construction, are affected by both European directives for construction products and electro-technical standards for PV products;

- Construction products must comply with harmonized standards where available, or the corresponding alternatives allowed by Construction Products Regulation;

- Further requirements for construction products are given by national building codes; and

- In the case of composite material-based construction products such as BIPV, most current standards seem to be not directly applicable/valid for testing some technical requirements (e.g. mechanical, fire safety, etc.).