What is the long-term reliability of BIPV?

BIPV products in general are amazingly stable against UV and weathering. Typical guarantees of performance extend now for 25 or 30 years, ensuring profitability of the installation well after the end of the depreciation period [cf. sheet 4.4]. Here is a review of ongoing work in the field.

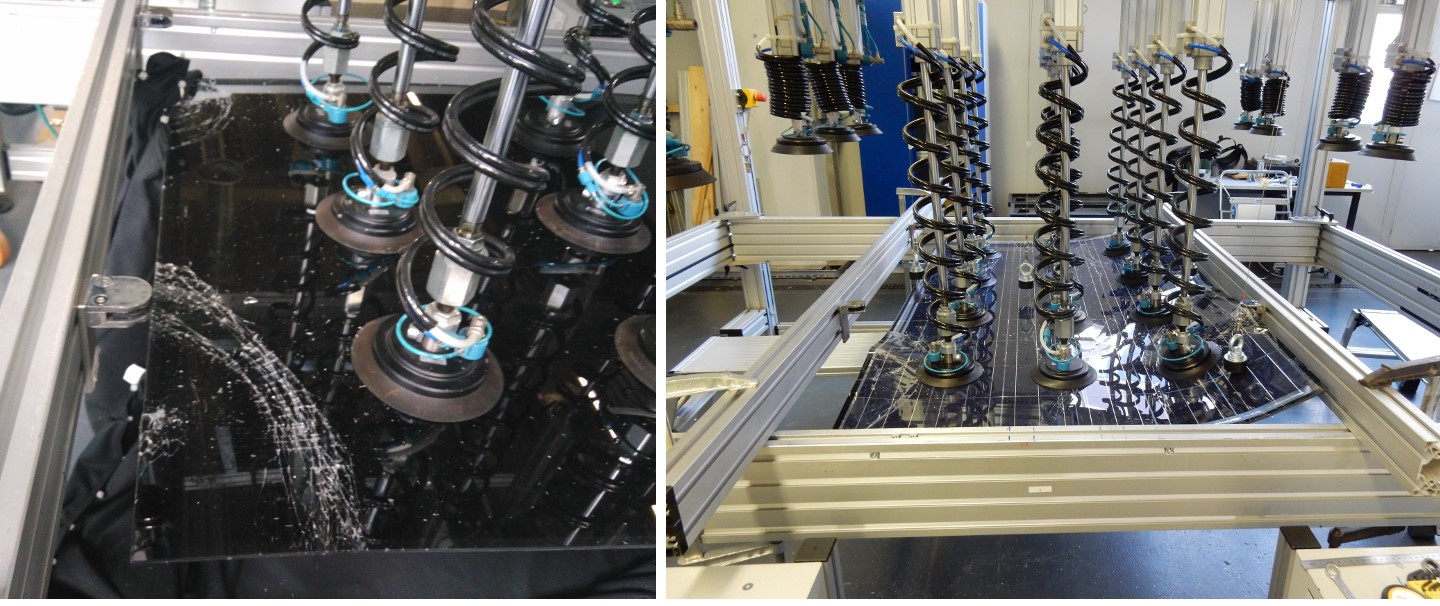

EN 61215 and EN 61646 qualification tests allow us mainly to identify initial short-term reliability issues of PV modules. Aging tests in climatic chamber and mechanical loads (Fig. 1) are also performed but it is important to note that there is no guarantee for PV modules to effectively sustain outdoor conditions and last for twenty or more years. Long-term reliability is a key issue for PV manufacturers and end-users. Nevertheless, it is not always considered in standards under preparation or covered by existing standards. For long-term reliability analysis, tests on PV modules are undergone by simulating accelerated stress tests based on measured data collected. Typical accelerating stressors are temperature, voltage, mechanical load, thermal cycling, humidity and vibration. Thus, in order to ensure long-term reliability of PV modules, it is important to identify their installation conditions and to adapt, accordingly, tests done indoors [1].

Moreover, there may be a need to differentiate between the lifetime for generating electricity (conventional PV) and the lifetime and reliability as a building component for a BIPV module. It remains to be seen whether the durability and reliability tests for conventional PV guarantee the performance of BIPV modules as part of building skin systems. Vice versa, it also remains to be seen whether the PV modules should undergo the same durability and reliability tests as their corresponding building element.

To combine the different functional requirements of building technique and electrotechnic in a BIPV product, BIPV qualification needs a special application.

According to EN 50583, Parts 1 and 2 "Photovoltaics in buildings", "Photovoltaic modules are considered to be building-integrated, if the PV modules form a construction product providing a function as defined in the European Construction Product Regulation CPR 305/2011.”

- BIPV glass as laminated safety glass (EN 14449) for facades and overhead installations;

- watertightness against driving rain and uneven snow loads on roof systems;

- flammability and fire reaction/resistance of construction materials;

- noise insulating and absorption properties;

- dynamic wind stress tests according to window and facade standards;

- heat and light transmission;

- reflection properties;

- adhesive strength with tensile and shear load tests.

- dynamic mechanical load (new IEC TS 62782:2016)

- temperature ranges in existing standards (61215) due to increased operating temperatures of BIPV modules

- PV as a source-of-fire (arcing).