What are technical solutions for lightweight BIPV?

Most facades can accommodate glass photovoltaic products [cf sheets 1.2 and 1.4]. Lightweight BIPV modules extend the range of possibilities for the cladding of buildings, especially for renovation projects. Here a new, reliable solution is presented.

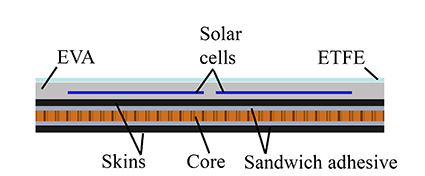

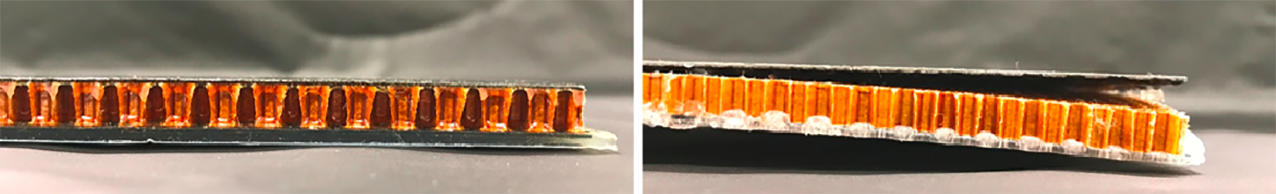

In this study [1-3], we propose a lightweight PV module based on c-Si technology with a weight of ~6 kg/m2. To reach this low weight, the standard front-glass is replaced by a thin polymeric sheet and the standard backsheet replaced by an innovative composite sandwich structure bringing the needed mechanical stiffness to the module. Fig. 1 shows all the materials used to produce the lightweight PV module, which includes a composite sandwich structure (composed of two skins and one core joined together with an adhesive), solar cells embedded in a polymer layer (EVA) and protected by a thin frontsheet (ETFE). Furthermore, our lightweight PV module can be processed in a single manufacturing process (including the processing of the composite sandwich backsheet).

The composite sandwich structure is responsible to provide the required rigidity to the PV module, thus this is the main component of the lightweight module. However, the main challenges during the design of such modules is to find a PV polymer adhesive that will provide a good stress transfer through the sandwich structure. Due to the use of different stacked materials with different thermal properties, the difficulty is to avoid early failure of the structure (composite sandwich) during a sub-set of IEC 61215 2:2016 industry standard qualification tests.

Thanks to optimal material selection (Fig. 2) and manufacturing parameters, medium-area modules composed of sixteen solar cells (81 cm x 81 cm) are manufactured using a standard flat-bed vacuum bag laminator, and processed in only 25 minutes. To pre-qualify our design, we used the relevant ac-celerated-aging test in use in the industry [4], which includes:

- Thermal cycling test - module is exposed to cyclical temperatures between 85°C and -40°C (200 cycles).

- Damp heat test - module is exposed to a temperature of 85°C and a relative humidity of 85% for a period of 1000 hours.

- Humidity freeze test - module is subjected to cyclical temperatures between 85°C (with rela-tive humidity of 85%) and -40°C.

- Hail test - module is shot at from different positions by ice balls of diameter ranging from 25-75 mm at specific velocities (23-39.5 m/s).

- Static mechanical load test - module is loaded on the front side with 2400 Pa for 1h and af-terwards with -2400 Pa for an additional 1h (3 cycles).